Production Control

Dedoussis Engineering is a registered System Integrator of AVEVA , providing solutions for the Chemical Industry, in Process Control of complex productions, Batch and continuous dosing, Reactor temperature Control, Polymers production and more with In Batch.

Flexible Batch Management

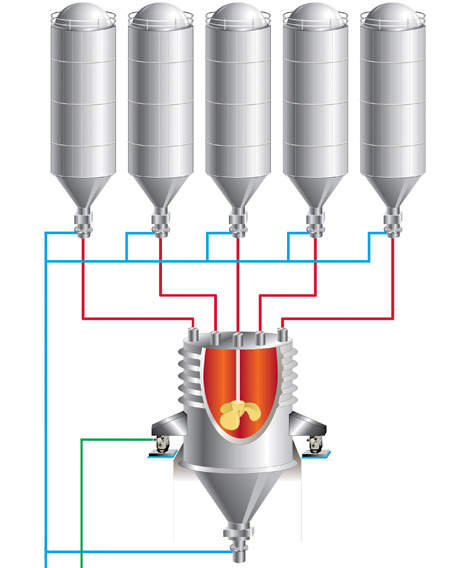

Batch Management software effectively manages flexible batch operations found in the process industries, including life sciences, fine chemicals, and food and beverage/CPG. Adhering to the ISA-88 standards for batch control, it provides guidance and oversight to both recipe management and batch execution. Batch Management software coordinates everything with the plant control systems, interfaces with the operators, and directs batch activity, material flow, and production data to a historical database for a full electronic batch record (EBR).Software packages from Minebea-Intec for both Automatic and manual dosing under the commercial names of ProBatch+, ProrecipeXT depending on the individuality of your process will cover your most strict demands.

Batch management ProBatch+ can manage a large number of materials pertaining to a production line.

With only a few operator steps, raw material quantities used and recipe quantities produced can be called up. Automatic stock monitoring is included. Material tracking with three freely selectable batch parameters and one data field can be activated optionally.

In ProBatch+ recipes are created in the

well-known Windows user interface.

Batch and special procedure steps, such as

mixing, heating, cooling etc. are registered

in the recipes. In addition, recipe steps

can execute powerful script functions for

humidity corrections of specified set points,

for synchronisation of process steps or

for the display of user dialogues. The script

functions make it possible to implement

rapid adaptations to new process require-

ments without the need to carry out expen-

sive programming in the PLC. Data can be

processed and stored at the recipe level,

production line level and installation level.

In addition, sub-recipes and correction

recipes, which can be repeated recurrently

to optimise product quality, are possible.

With ProBatch+ several batches of a recipe

can be executed within one production run.

Production plans can be produced for each

production line individually and executed

both automatically and by user enabling.

At any time the user has a clear overview

of the entire production and can intervene

when necessary. Operating errors are

avoided by means of graphic highlighting

of currently permitted commands.

The current process status is constantly

indicated for each balance and each

production line. This includes gross weights,

orders, current recipes and components with

specified and actual values, and the status

of the batch controllers. Alarms and system

messages are each highlighted in colour

and gathered in a separate list window.

At the end of every recipe run ProBatch+

generates batch and production reports.

Material management makes available

reports on consumption, production

quantities and stock levels.

In ProBatch+ recipes are created in the

well-known Windows user interface.

Batch and special procedure steps, such as

mixing, heating, cooling etc. are registered

in the recipes. In addition, recipe steps

can execute powerful script functions for

humidity corrections of specified set points,

for synchronisation of process steps or

for the display of user dialogues. The script

functions make it possible to implement

rapid adaptations to new process require-

ments without the need to carry out expen-

sive programming in the PLC. Data can be

processed and stored at the recipe level,

production line level and installation level.

In addition, sub-recipes and correction

recipes, which can be repeated recurrently

to optimise product quality, are possible.

With ProBatch+ several batches of a recipe

can be executed within one production run.

Production plans can be produced for each

production line individually and executed

both automatically and by user enabling.

At any time the user has a clear overview

of the entire production and can intervene

when necessary. Operating errors are

avoided by means of graphic highlighting

of currently permitted commands.

The current process status is constantly

indicated for each balance and each

production line. This includes gross weights,

orders, current recipes and components with

specified and actual values, and the status

of the batch controllers. Alarms and system

messages are each highlighted in colour

and gathered in a separate list window.

At the end of every recipe run ProBatch+

generates batch and production reports.

Material management makes available

reports on consumption, production

quantities and stock levels.All reports can be adapted to customer requirements, since they are generated using the Crystal Report Generator. By means of an integrated security system users with different access rights can be logged on. This prevents operator error and avoids unnecessary batch faults. The clear and user-friendly operator interface is supported by the incorporation as standard of almost every European language (see below). All texts can be adapted to location or installation specific conditions. The languages can be changed during operation. In this way ProBatch+ is applicable globally and is quick to learn. A detailed Help function is integrated and is available in English and German.